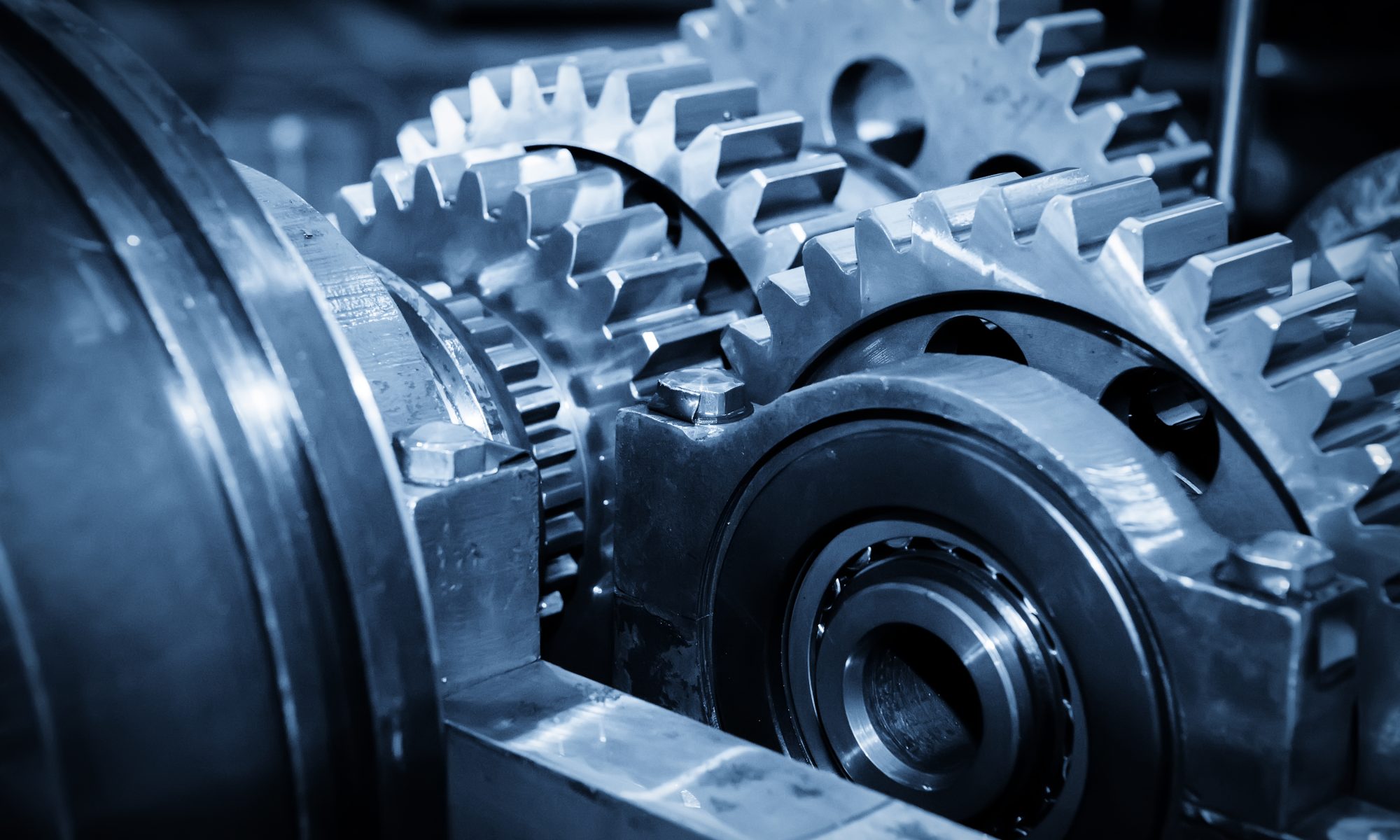

The Internal Clearances of Roller Bearings help in providing optimal working conditions to bearings which results in longer service life and optimum performance. This blog covers some of the best fitting practices of roller bearings to help you understand them in a better way.

The Initial bearing clearance is the distance by which one bearing ring can be freely displaced in relation to the other ring when not mounted. With axial clearance, the bearing ring is displaced along its axis, with radial clearance vertically to the bearing axis.

When The Bearing is Installed For example on the shaft, some of the initial clearance is lost as the Fitment of the inner ring on the shaft, the clearance left with the bearing after fitment is the operating Clearance.

Internal Clearances & Fitting Practices of Roller Bearings

Here are some of the aspects related to internal clearances that one should refer to while fitting the roller bearings:

1. Selection of Fits: The bearings are usually fit using force locking to ensure that they achieve optimum performance as per their functioning. The primary consideration of it is to ensure that bearing rings are well supported in terms of circumference to utilize optimum load carrying capacity of bearing. Another aspect is that the non-locating bearing should accommodate changes in length to give scope for axial displacement.

2. Calculating Internal Radial Clearance: This can be referred to as the geometrical calculation between the outer ring, inner ring and ball of a bearing. As the bearing may produce heat while operating within the machinery, there are some calculations required in terms of internal clearances to prevent excessive heat generation.

3. Geometric and Positional Tolerances: The roughness contained in the bearing seats should adequately match up to the right tolerance class of bearing. Failure of this can result in wear and tear or breakdown.

4. Fitting Bearings as per International Standards: There are varied international standards like ABMA, ISO, ANSI, etc. which specifies the fits and tolerances of bearings through a combination of letter and a 6-digit number. It is recommended to follow such standards to perfectly fit the bearings without any constraints. The different bearing providers offer this information in their bearing installation manuals.

5. Ensure Clean Area while Mounting Bearings: The dust or unclean environment can result in internal machinery or bearing getting exposed to it. While this can be dangerous, it can also result in damage to rolling surfaces.

Conclusion

In most cases, there can be one or more bearings supporting the machinery. While one can be a rotating element or the other can be non-locating, various crucial factors are taken into consideration while fitting the bearings. As this blog has covered some of those aspects, these practices must be followed strictly to optimize the bearing performance and give it longer service life.